As a one-stop provider of all professional services associated with racking, storage and material handling needs, we have become the trusted resource partner for clients all across North America.

Explore Our Selective Pallet Rack Configurations

Single-Deep

Double-Deep

Back-to-Back

Narrow Aisle

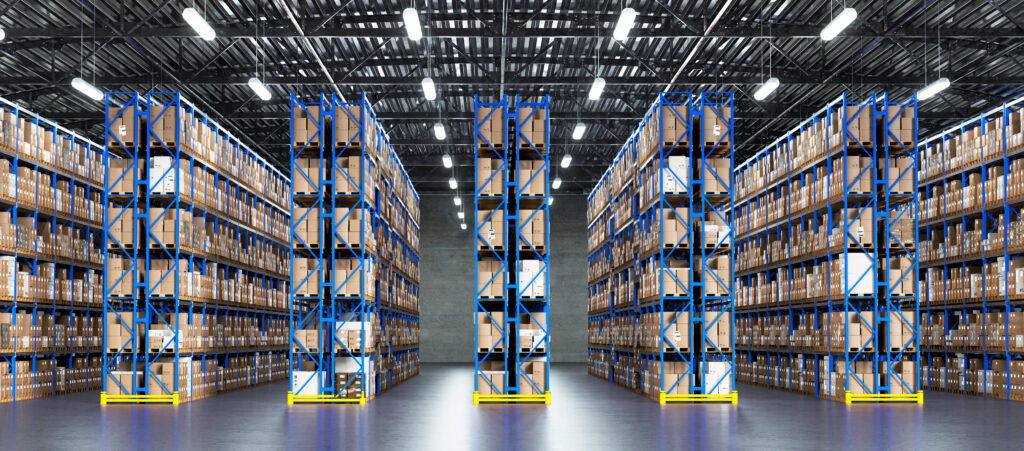

Warehouse Storage Basics: What is Selective Racking?

Key Benefits:

- 100% pallet access – Fast picking and put-aways

- Cost-effective – Low upfront & maintenance costs vs. high-density systems

- Highly flexible – Adaptable to different pallet sizes, weights, and inventory volumes (decking may be required)

- Easy to maintain – Minimal components, straightforward repairs

How Selective Pallet Racking Works

Upright frames vertical supports that are anchored to slab

Load beams horizontal beams that carry the pallets

Wire decking or pallet supports added safety and support

Row spacers required in back-to-back row configurations

Rack protection & stability column guards, end row guards, and overhead ties

Versatile Applications Across Industries

Here are just a few of the environments where selective pallet racking excels:

Retail & E-commerce:

High turnover and wide product variety demand quick picking and easy inventory rotation.

Food & Beverage:

Ideal for facilities using FIFO systems to manage perishable goods. Direct access to each pallet and ability to use Very Narrow Aisle configuration, which is useful in the cold storage applications that pharmaceuticals often need to have.

3PL & Distribution Centers:

Flexibility to handle diverse client inventories with frequent stock changes.

Manufacturing:

Streamlines raw material and finished goods storage for just-in-time production.

Did you know?

Selective pallet racking remains the most commonly used racking system across U.S. warehouses, thanks to its cost-effectiveness and flexibility.

It supports both FIFO and LIFO workflows.

Installation is fast and scalable, making it a great option for businesses expanding or reconfiguring warehouse space.

Many selective rack systems can be relocated or reused, helping reduce capital costs during facility changes.

Choosing the Right Configuration

- Product dimensions and weight Ensuring your racking supports the right load capacity and storage type.

- Inventory storage requirements Quantity of pallets and picking strategy as needed.

- Forklift types and maneuverability Matching aisle widths and rack heights to your existing or planned equipment.

- Seismic considerations and safety standards Assuring full compliance with all applicable local and national codes.

- Available floor space and vertical clearance Maximizing your cubic storage potential without compromising accessibility.

Purpose-Built Selective Racking Solutions Backed by Decades of Expertise

Source top-quality selective racking materials and proven hardware

Through our vendor network, we offer access to durable, performance-grade racking systems tailored to your specifications.

Meticulously plan and clearly communicate every project detail

From initial site assessments to CAD layouts, scheduling, and permitting, we keep your project aligned and on track.

Tailor configurations to match your unique inventory, equipment, and goals

We design for flexibility, ensuring your racking system supports your workflow today—and scales with you tomorrow.

Maintain a commitment to professionalism and quality at every step

Catalina is known for thorough execution, transparent communication, and safety-focused installation.

Drive measurable improvements in space utilization and operational flow

Our solutions are engineered to make your warehouse more productive from day one.